Design Projects

This section includes projects that I have worked on. This includes both the engineering side of things, the drawings and design of the physical product and the mechanics behind it; as well as the visual side of the projects. “Look good feel good” is something I take to heart when designing things for either myself or others.

Bivo shelf display: June 2023- Present

This project is still in progress. There have been many iterations of this shelving display trying to perfect the fit of the bottles on the shelf. One of the requirements for this shelf was for it to come apart and lay flat together to allow it to travel easily. It also needed to be light, and allow for 12 bottles to be displayed evenly, while showing the character of the company. This display was designed first in solidworks and then put together to check the fit. The files were then transferred to adobe illustrator to make the final touches and to change them into dxf to allow for cncing.

Bivo Floating Display: April 2023

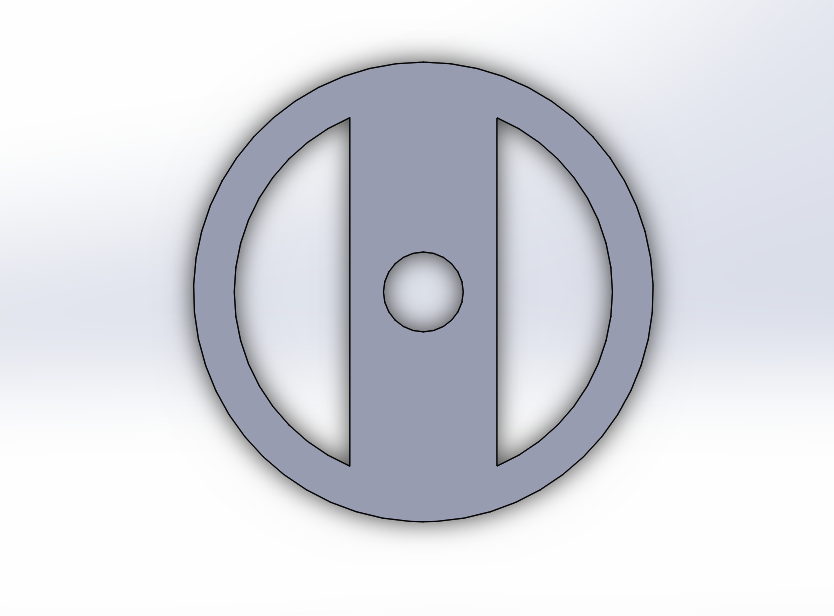

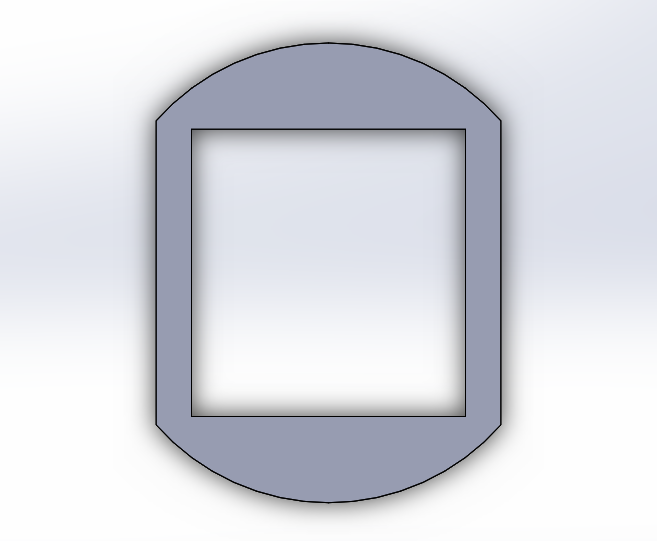

This project was done for the small startup company Bivo located in Richmond Vermont. This company makes metal bike bottles to decrease plastic waste. This display was designed to show the key function of the bottle that separates it from others. The Bivo bottle has a higher flow rate of any bottle and has a seamless flow once the cap is open. I designed 3 pieces to help keep the top bottle up and make the appearance of it floating. These three pieces are shown to the right. The final result can be seen in the video.

Prosthetic Snowboard Adapter: September 2022-April 2023

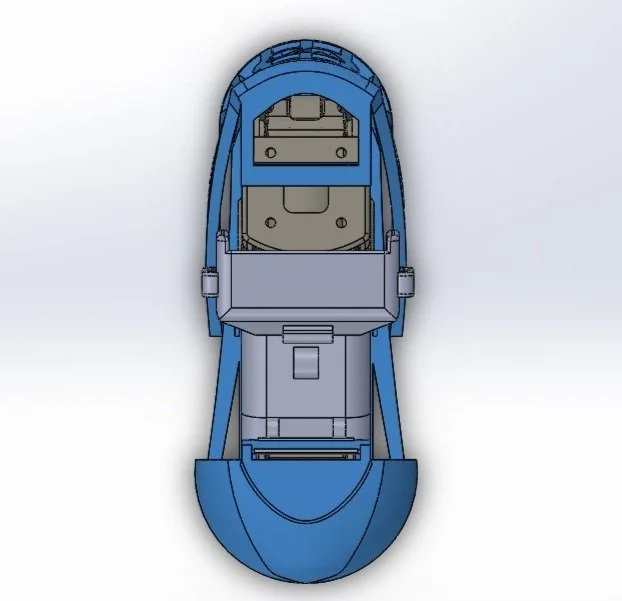

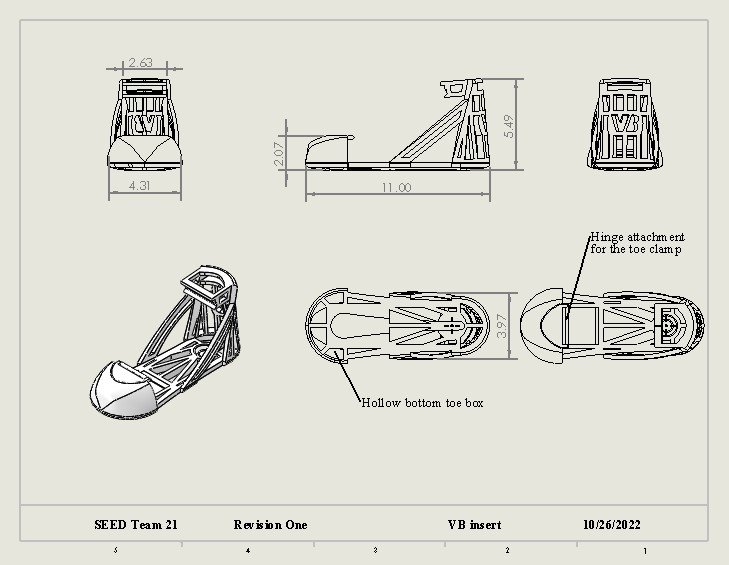

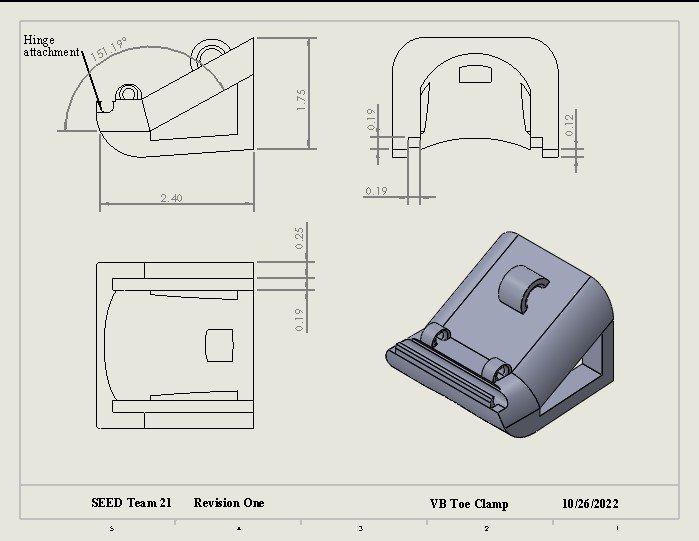

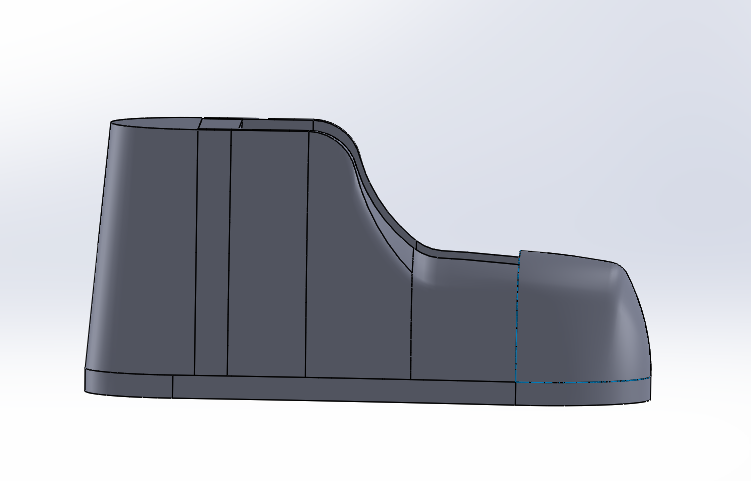

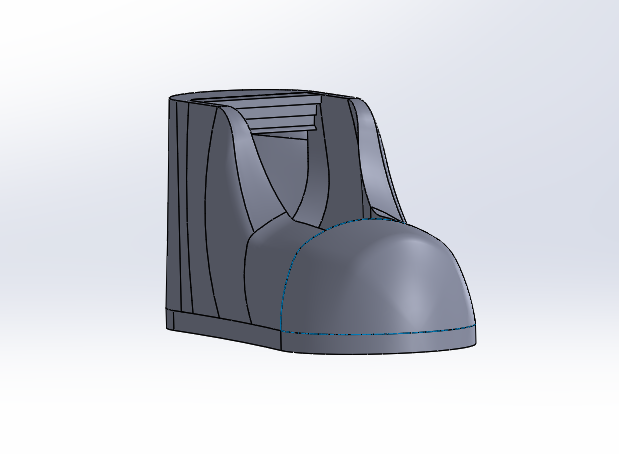

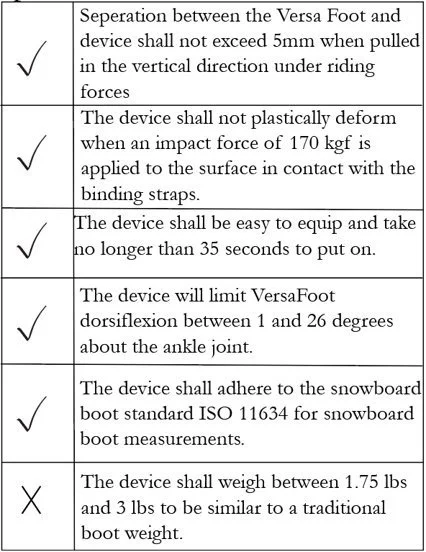

This project is done through the Senior Experience in Engineering Design (SEED) class at University of Vermont. This is a student lead team of four engineering students, with no outside support from a company, and a budget of $1000 from the university. The issue that below the knee amputees face is the lack of boots available to fit prosthetics. Currently the Versa Foot is the leading prosthetic for outdoor sports. The solution many athletes have is to put the foot into a snowboard boot, which takes about 20 minutes, and then it is left there until the end of the season. There are many issues with this solution; one being that they are leaving a $10,000 foot in a boot for months on end, and another being that they have to completely change their leg to go into the lodge. This approach also creates gaps between the prosthetic and the snowboard boot. My teams job is to design a boot specifically for the Versa Foot. After delegating work to each members strong suit, my role as the only design engineer is a majority of the Solidworks and concept design. Throughout the process there have been 3 iterations of the boot itself, shown to the left, and many tests done as well as engineering specifications written for the final product. The final product is still a work in progress, but the goal of the team is to have a functional boot including an outer layer by the end of April, 2023.

Click the video to watch how the boot would work to hold the foot in place. In practice, there are BOA systems to strap both the ankle clamp and toe clamp down onto the foot.

Updated Design (3/20/2023)

This new design takes into consideration all of the problems identified through testing of the old prototype, and keeps the parts that worked well. This new design also makes it easier to equip with an outside layer to make the boot look similar to an able bodied snowboard boot.

The final Engineering Specifications results:

Click the video to see how the boot is equiped onto the VersaFoot.

Final Design April 28th 2023: The team printed the solidworks files shown above using an SLS printer. The outer layer of fabric was then added afterward to add an additional layer of support and protection. The boa dials are rooted into the solidworks design.

Dirt Jumper design: January 2022

I completed this project out of a need for a dirt jumper, but with covid, there were none available. My father is a custom steel frame builder, and I grew up watching him work and wanting to do one myself. My goal was to create a dirt jumper that fit me perfectly. I started this process with a drawing on paper as shown, and then moved to the jig which held the steel tubes in place at the correct angles while I marked and cut the tubes. My brother helped out with this project too. He welded the tubes together to create the frame, and then I got to designing the visual part of the bike. I decided to make it match my other bikes as well, which are shown further down.

Liv Hail/ Cyclocross bike Redesign: May 2020- September 2020

Both of these projects were born out of my love to make everything match. I started with my Liv Hail that I had been riding for 3 years and I was starting to get sick of the neon blue color that truly did not match my personality. I took the bike apart and removed all of the bearings before sanding the carbon linkage part, and sandblasting the rest of the frame and the rear triangle. Next, an airbrushed coat was sprayed to seal the frame, and a black base coat was applied. Acrylic paints were used to hand paint the flowers. The rear triangle of the bike was powder coated to match my cyclocross bike in my signature purple. My cyclocross bike then matched, but did not have any flowers, so I used the same acrylic paints to paint flowers on the fork of the bike, to make an inverse sort of match of the bikes. My dirt jumper came last, and I used the same methods to paint the frame as talked about before.

Before

After

Before

After

Hardtail Design: September 2019

This project is the one that started my love for painting bikes. I needed a hairtail racing bike for my xc races, and I wanted it to look like a notebook doodle. I helped my dad with the drawings and jig set up of this bike, and then it got powder coated white for a base. I then used acrylic paint pens to draw on the frame to give it the look I wanted. This was my first attempt at painting my own bike, and it definitely has led to some improvements. I have learned from this project to put a clear coat on top to seal the paint so that it does not rub off, and which paint pens work the best.